A vibratory polishing machine is an essential tool in various industries for achieving smooth, polished surfaces on metal, plastic, ceramic, and other materials. These machines use vibration to help polish and finish the surfaces of workpieces quickly and efficiently. In applications ranging from deburring to edge radiusing, vibratory polishing has gained recognition for its precision and cost-effectiveness. This article will delve into how these machines work, their applications, advantages, and maintenance, providing a comprehensive guide on their use.

How Vibratory Polishing Machines Work

Principles of Vibratory Polishing

Vibratory polishing machines use a mechanical system to create oscillating motion, which causes polishing media (such as ceramic, plastic, or steel) to move around and interact with the workpieces. This motion creates the desired finish by wearing down the surface of the material, removing rough edges, and smoothing the texture. The vibratory motion can be circular, linear, or elliptical, depending on the machine’s design.

Key Components of a Vibratory Polishing Machine:

Bowl/Tub: The container that holds both the workpieces and the polishing media.

Vibration System: The mechanical or electromagnetic system that generates the vibrations.

Media: Abrasive materials that help achieve the polishing effect.

Workpieces: The items being polished, which are placed inside the bowl.

Types of Vibratory Motion Used in Polishing

Different types of vibratory motion are employed to suit specific polishing needs:

Circular Motion: Commonly used for general polishing tasks.

Linear Motion: More efficient for larger or more delicate workpieces.

Elliptical Motion: Offers a combination of both linear and circular motion, providing better coverage and efficiency.

Applications of Vibratory Polishing Machines

Vibratory polishing machines are used in a wide range of industries, primarily for improving the surface finish and quality of workpieces. These machines are most commonly employed in sectors where mass finishing is essential.

Industries That Benefit from Vibratory Polishing:

Automotive Industry

Vibratory polishing is used to smooth metal components, improve appearance, and ensure that parts are free from burrs, which is crucial for both aesthetics and safety.

Metalworking

In metalworking, these machines help remove rust, oxidation, and scale from metal parts while also smoothing surfaces to create a more polished and uniform finish.

Electronics

For the electronics industry, vibratory polishing is used to refine small metal parts or components that require precise finishes.

Jewelry Manufacturing

The jewelry industry uses vibratory polishing machines for polishing precious metals and ensuring a high-quality, glossy finish.

Aerospace and Defense

These machines are critical in aerospace manufacturing, where the precision and smoothness of the components are paramount for safety and efficiency.

Common Use Cases in Vibratory Polishing:

Surface Finishing: Achieving a smooth, shiny finish on parts.

Deburring: Removing unwanted burrs from edges to prevent sharp edges.

Edge Radiusing: Creating rounded edges on parts to avoid sharp corners.

Polishing: Enhancing the aesthetics of the parts, improving corrosion resistance.

Advantages of Using Vibratory Polishing Machines

Efficiency and Speed

Vibratory polishing machines are known for their high-speed processing capabilities. The vibration-driven motion results in fast material removal and surface finishing, reducing the time needed for manual polishing processes. This makes them highly efficient, especially for mass production lines where large batches need to be processed.

Precision and Consistency

One of the key benefits of vibratory polishing is its ability to provide consistent surface finishes. The controlled environment within the machine ensures uniform results on every workpiece, reducing variability that can be seen with manual polishing or other methods. This precision is essential for industries such as aerospace, automotive, and electronics.

Versatility

Vibratory polishing machines can handle a wide variety of materials, including metals (e.g., aluminum, steel, titanium), ceramics, and plastics. They are suitable for both small and large workpieces and can be used to polish complex geometries, which may be difficult to process with other types of polishing equipment.

Cost-Effectiveness

Compared to other polishing methods like hand polishing or tumbling, vibratory polishing is more cost-effective due to its automation and reduced labor costs. The machines are efficient in terms of power consumption, and the reusable nature of media makes the process less expensive in the long term.

Types of Vibratory Polishing Machines

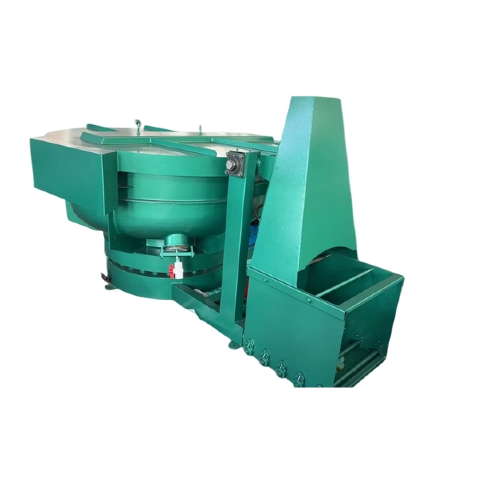

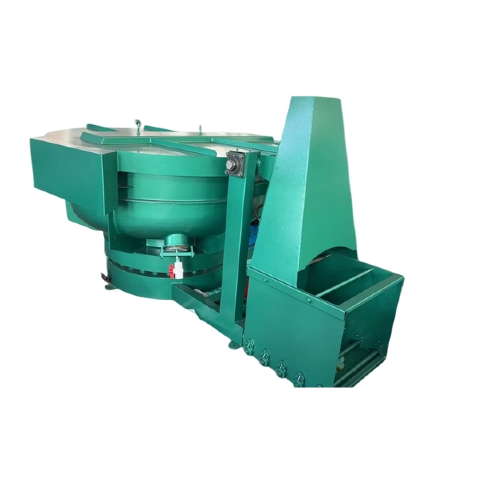

Bowl-type Vibratory Polishing Machines

Bowl-type vibratory polishing machines are one of the most commonly used types in industries requiring polishing, deburring, or cleaning. These machines feature a rounded, bowl-like shape where the workpieces and media are placed. The bowl is vibrated by the system, causing the workpieces to tumble against the media.

Applications: Small to medium-sized parts in various industries.

Features: Easy to operate, space-efficient, and suitable for both batch and continuous processing.

Tub-type Vibratory Polishing Machines

Tub-type machines have a rectangular design and are ideal for polishing larger or more complex parts that may not fit in a standard bowl-type machine. They are often used in industries requiring a larger volume of parts or continuous finishing.

Applications: Larger workpieces such as automotive components, heavy machinery, and industrial tools.

Features: Capable of handling larger batches, suitable for heavy-duty polishing tasks.

Continuous Vibratory Polishing Systems

Continuous vibratory polishing systems are designed for high-volume production and are often used in industries where parts must be polished on an ongoing basis, such as in the automotive and electronics industries.

Applications: Mass production, automotive manufacturing, and industrial-scale deburring.

Features: Automated feeding systems for continuous input and output, maximizing efficiency and throughput.

Vibratory Polishing Media

The type of polishing media used in vibratory polishing machines plays a critical role in achieving the desired surface finish. The choice of media depends on the material of the workpiece and the type of finish required.

Media Type | Best for | Characteristics |

Ceramic Media | Metals, ceramics, plastics | Harder media, provides a smooth finish |

Plastic Media | Lightweight materials, plastics | Softer media, reduces wear on delicate surfaces |

Steel Media | Harder metals, high-volume jobs | High durability, often used for heavier or more rugged finishes |

Walnut Shells | Jewelry, fine metal parts | Natural material, used for a softer, more gentle polish |

Choosing the Right Media:

Ceramic Media: Ideal for metals and harder materials, provides a smooth and polished finish.

Plastic Media: Works well with softer metals and materials, ideal for delicate parts.

Steel Media: Used for hard metals or industrial-scale polishing tasks requiring durability.

Factors Influencing Vibratory Polishing Results

Several factors influence the quality of the polishing process. These factors include:

Polishing Time: Longer polishing times typically result in smoother finishes, but excessive polishing can lead to material loss.

Media Type: Different media types affect the aggressiveness and texture of the finish.

Vibration Intensity: The force of the vibration can be adjusted to suit different materials and desired finishes.

Workpiece Size and Shape: Larger or more complex shapes require different setups and longer processing times.

Maintenance and Care of Vibratory Polishing Machines

Proper maintenance ensures that a vibratory polishing machine operates at peak efficiency for as long as possible. Here are key maintenance tasks:

Routine Maintenance:

Inspect the Bowl: Ensure there are no cracks or damages to the bowl that may cause leaks or inefficiency.

Check Vibration Mechanism: Ensure the vibration mechanism is functioning properly to maintain optimal motion.

Clean the Media and Workpieces: Regularly remove debris from the media and workpieces to ensure a high-quality finish.

Media Maintenance:

Media needs to be replaced or cleaned regularly to maintain polishing effectiveness. Over time, media can become less effective at polishing due to wear.

Conclusion

Vibratory polishing machines are highly versatile, efficient, and cost-effective solutions for surface finishing, deburring, and polishing. With a wide range of applications across various industries, these machines are crucial for manufacturers aiming to enhance their production processes. Their ability to process diverse materials, deliver precise finishes, and reduce labor costs makes them an ideal choice for both small-scale and large-scale operations.

At Huzhou Antron Machinery Co., Ltd., we specialize in providing top-quality vibratory polishing machines designed to meet the needs of different industries. Our machines offer superior performance, ensuring optimal results while minimizing production time. Whether you’re looking to improve the finish of metal, plastic, or other materials, our solutions are built to deliver exceptional results every time.

For more information about our products or to discuss your specific requirements, feel free to contact us. Our team is ready to assist you in selecting the right vibratory polishing machine for your needs, helping you achieve greater efficiency and enhanced product quality.

FAQs

1. What types of materials can be polished using a vibratory polishing machine?

Vibratory polishing machines can handle a wide range of materials including metals (aluminum, steel, titanium), plastics, ceramics, and composites. The media and settings can be adjusted to suit each material.

2. How long does it take to achieve a polished finish with a vibratory polishing machine?

The time required for polishing depends on factors like the material, size of the workpieces, and media type. Typically, polishing can take anywhere from a few minutes to several hours.

3. Can vibratory polishing machines be used for mass finishing?

Yes, vibratory polishing machines are excellent for mass finishing applications. Their continuous nature and ability to handle large volumes make them ideal for mass production environments.

4. How do you choose the right vibratory polishing machine for your needs?

The choice of machine depends on factors such as the size of the workpieces, desired finish, and production volume. Bowl-type machines are suitable for smaller batches, while tub-type or continuous systems are better for larger or more complex parts.

5. Is it possible to automate the vibratory polishing process?

Yes, many vibratory polishing systems are designed for automation, with automated feeding, draining, and output systems that enhance productivity and reduce labor costs.