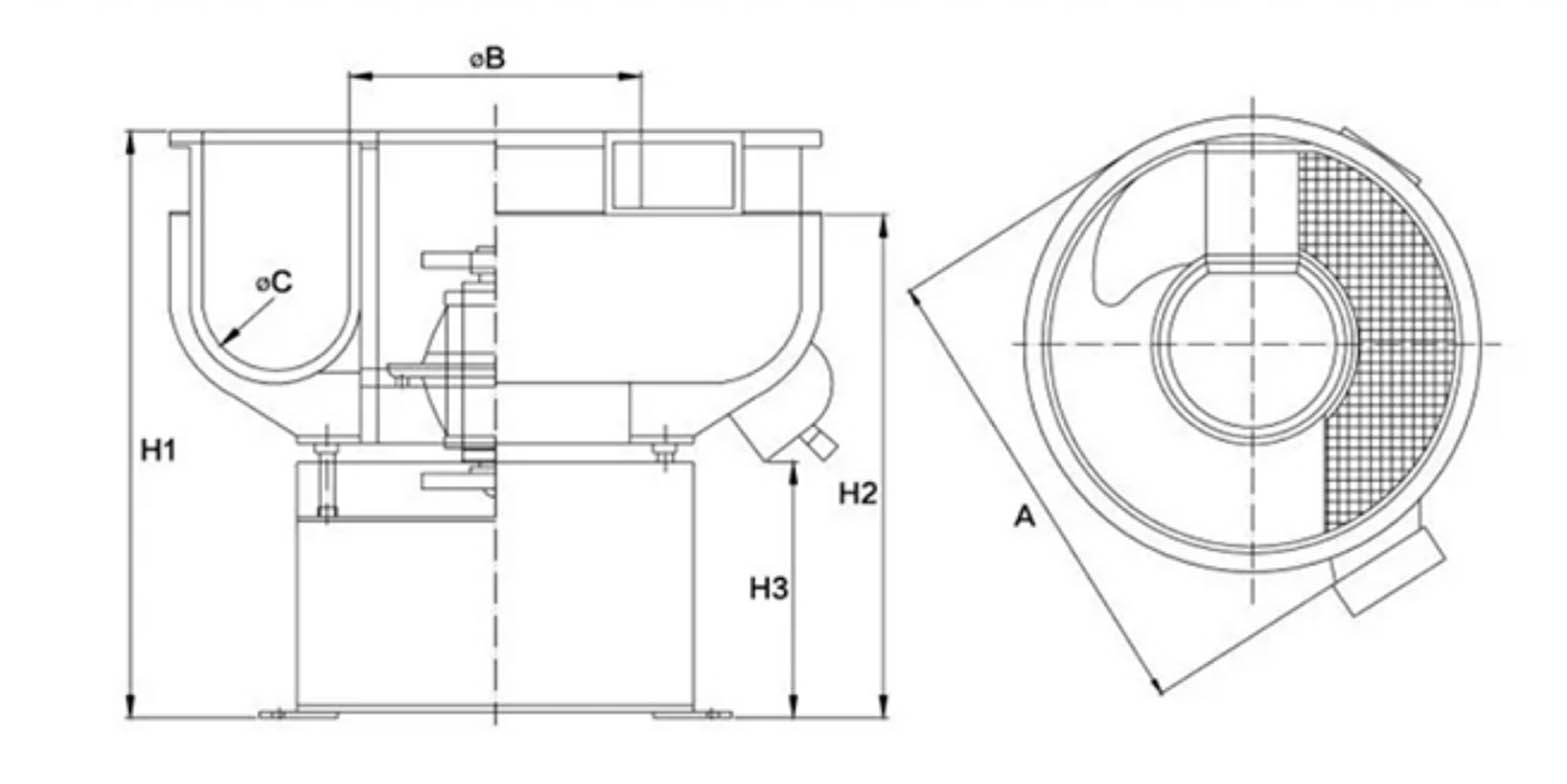

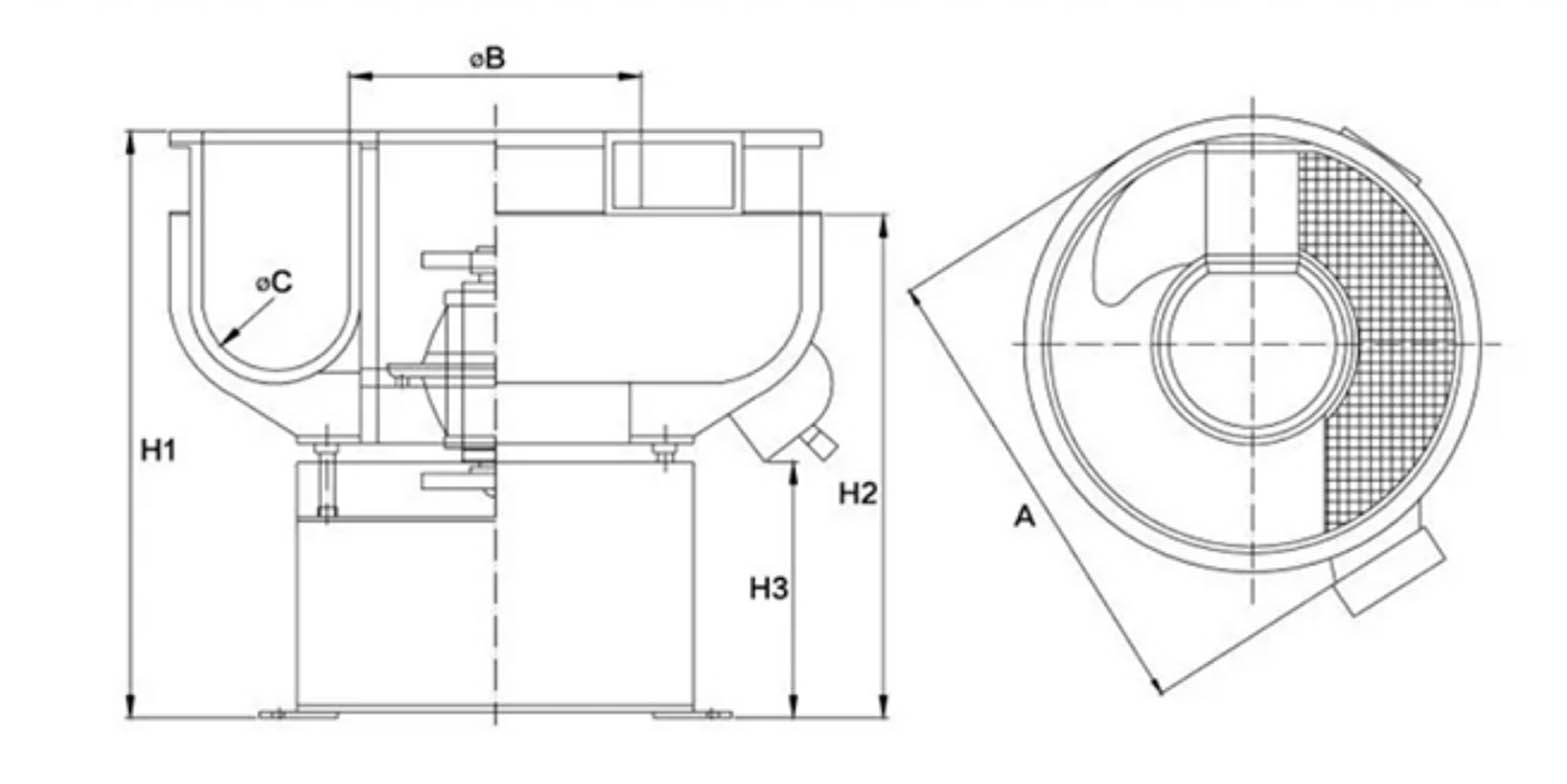

Description of Steel Plastic Silver Vibratory Finishing Machine:

Antron Machinery's AHM series vibration polishing machine operates on the principle of generating three-dimensional high-frequency vibrations within a ring chamber, where the grinding media and workpiece are contained. The machine can effectively eliminate burrs, sharp edges, corners, rust, oil stains, etc., thereby achieving a certain level of finishing, smoothness, and brightness on the surface of the part.

Technical data:

Model

|

Volume/L | Max overall Dimension A/MM | Motor installation tube B/MM | Process bowl width C/MM | Unload width D/MM | Machine height H1/MM | Machine height H2/MM | Machine height H3/MM | Motor power/KW | Weight/KG |

ABS(B)100 | 100 | 1080 | 460 | 220 | 250 | 980 | 800 | 470 | 1.5/2.2 | 280 |

ABS(B)150 | 150 | 1170 | 460 | 260 | 210 | 860 | 710 | 440 | 2.2 | 320 |

ABS(B)200 | 200 | 1200 | 530 | 252 | 250 | 940 | 770 | 360 | 3 | 460 |

ABS(B)300 | 300 | 1370 | 630 | 275 | 320 | 960 | 760 | 290 | 3.7/5 | 650 |

ABS(B)400 | 480 | 1430 | 630 | 330 | 380 | 1270 | 1090 | 570 | 5 | 780 |

ABS(B)600 | 660 | 1860 | 900 | 390 | 470 | 1140 | 925 | 400 | 5.5/7.5 | 1180 |