Installation operationof Strong And Durable Surface Powder Coating Equipment:

1. Please ensure that the installation position is flat and stable before installation

2. Install equipment correctly according to installation videos or drawings.

3. Check whether the power and air supply of the equipment are normal.

4. Place the powder box on the vibration plate.

5. Set ventilation

6. Set spraying parameters

→ Use the "ON" button to turn on the spray gun controller

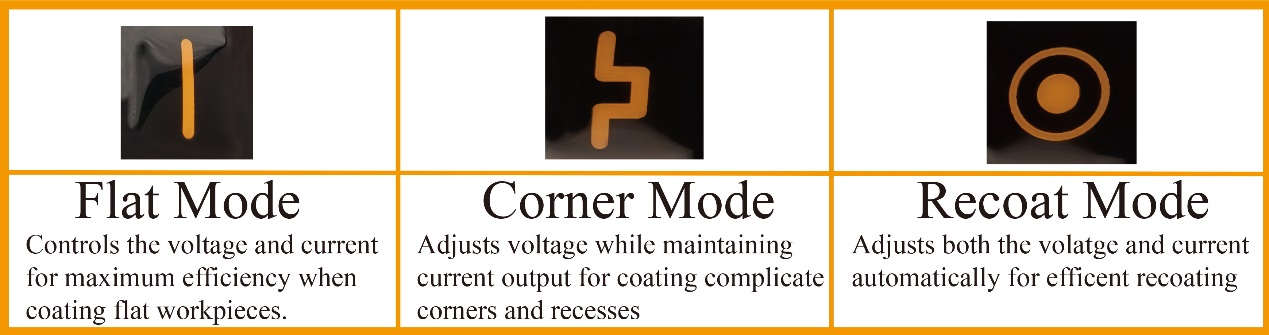

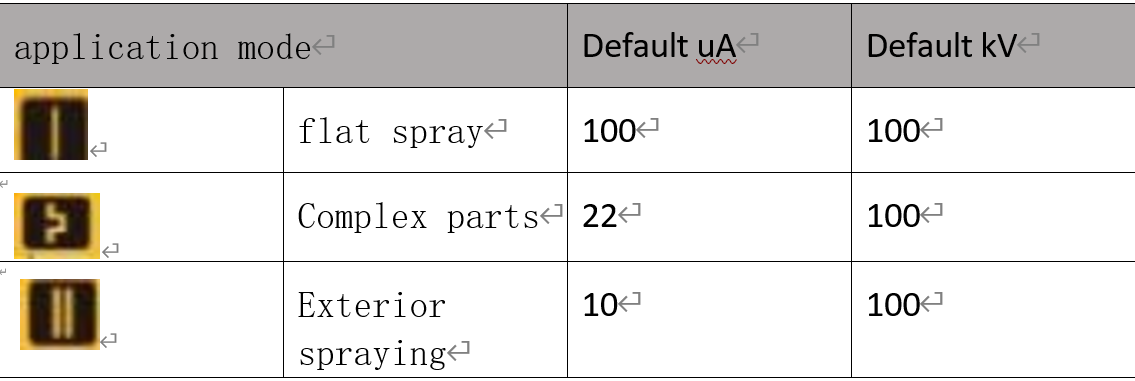

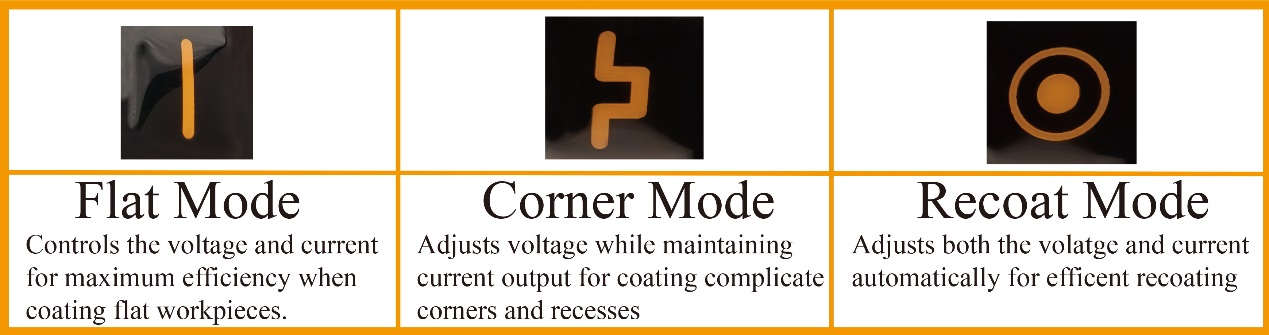

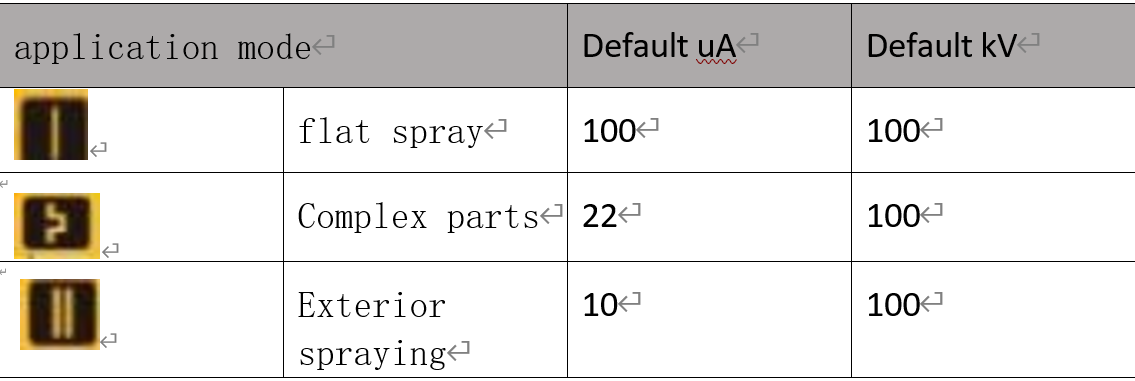

→ Select the workpiece to be sprayed

7. The total air volume, powder output, and air values for electrode cleaning airflow can be defined separately and saved in the program.

→Use the "ON" button to turn on the spray gun controller

→Press the

program key to select the desired program (01-20)

Change spraying parameters as needed Programs 01-20 have been pre-set at the factory, but can be modified at any time and automatically saved.

Powder output | 60% |

Total air volume | 4.0Nm3/h |

High voltage | 80kV |

Spraying current | 20uA |

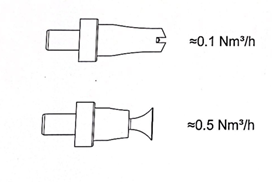

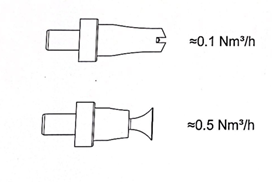

Fluidizing air | 1.0Nm3/h(applicable to F-type equipment) 0.1Nm3/h (applicable to type B equipment and type S equipment) |

8. Set powder output and powder mist:

As the factory default value, it is recommended to have a powder rate of 50% and a total air volume of 4Nm3/h. If a value that cannot be executed by the spray gun controller is input, the operator can be informed of the situation through the relevant display screen flashing and temporary error messages.

9. Set total air volume:

→Adjust the total air volume of the spray gun controller through the② /③key (See product structure diagram)

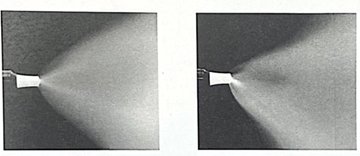

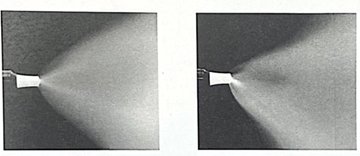

Correct powder cloud Total air volume is too little

→Check the airflow of the powder in the powder box

→Point the spray gun toward the powder booth, turn on the spray gun, and visually inspect the powder output

10. Set up electric-level air blowing

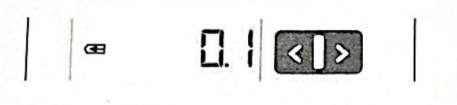

→Press  button, the second level display page will be displayed

button, the second level display page will be displayed

→Adjust the correct electrical blowing air flow according to the nozzle of the application .

→If there is no operation for 3 seconds on this display page, it will switch to the first level display page independently.

11. Set up streaming

Fluidization can be adjusted on the manual unit.

Powder fluidization depends on powder type, air humidity and ambient temperature. Fluidization or vibration is initiated via the controller.

→Press  button, the second level display page will be displayed

button, the second level display page will be displayed

→Adjust the fluidizing air with buttons ④/⑤

→If there is no operation in this display page for 3 seconds, the device switches back to the first-level display page.

→Touch the powder only lightly, but make sure it is "boiling" and stir with a stick

12. stop running

→End the spraying process and turn off the controller(Save the adjustment values of high voltage, powder output and electrode cleaning air flow).

→Disconnect power and clean gun, emitter and powder hose.

→Turn off the compressed air power supply.

button, the second level display page will be displayed

button, the second level display page will be displayed